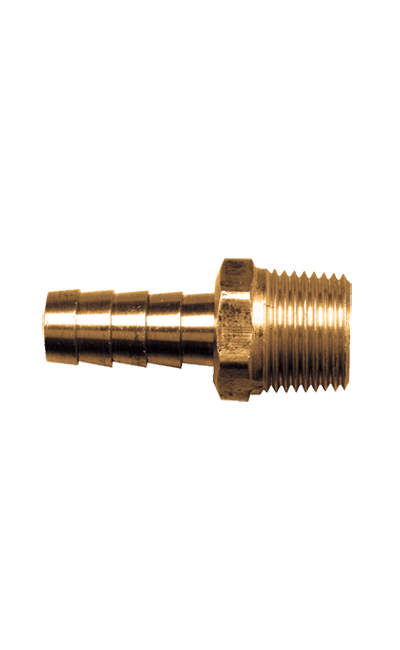

Part Number

Description

- FAI 125-2-10/32 1/8" Hose ID x 10/32" MPT

- FAI 125-2A 1/8" Hose ID x 1/8" MPT

- FAI 125-2B 1/8" Hose ID x 1/4" MPT

- FAI 125-3A 3/16" Hose ID x 1/8" MPT

- FAI 125-3B 3/16" Hose ID x 1/4" MPT

- FAI 125-4A 1/4" Hose ID x 1/8" MPT

- FAI 125-4B 1/4" Hose ID x 1/4" MPT

- FAI 125-4C 1/4" Hose ID x 3/8" MPT

- FAI 125-4D 1/4" Hose ID x 1/2" MPT

- FAI 125-5A 5/16" Hose ID x 1/8" MPT

- FAI 125-5B 5/16" Hose ID x 1/4" MPT

- FAI 125-5C 5/16" Hose ID x 3/8" MPT

- FAI 125-6A 3/8" Hose ID x 1/8" MPT

- FAI 125-6B 3/8" Hose ID x 1/4" MPT

- FAI 125-6C 3/8" Hose ID x 3/8" MPT

- FAI 125-6D 3/8" Hose ID x 1/2" MPT

- FAI 125-6E 3/8" Hose ID x 3/4" MPT

- FAI 125-8B 1/2" Hose ID x 1/4" MPT

- FAI 125-8C 1/2" Hose ID x 3/8" MPT

- FAI 125-8D 1/2" Hose ID x 1/2" MPT

- FAI 125-8E 1/2" Hose ID x 3/4" MPT

- FAI 125-10C 5/8" Hose ID x 3/8" MPT

- FAI 125-10D 5/8" Hose ID x 1/2" MPT

- FAI 125-10E 5/8" Hose ID x 3/4" MPT

- FAI 125-12D 3/4" Hose ID x 1/2" MPT

- FAI 125-12E 3/4" Hose ID x 3/4" MPT

- FAI 125-16E 1" Hose ID x 3/4" MPT

- FAI 125-16H 1" Hose ID x 1" MPT

- FAI 125CA-8D 1/2" Hose ID x 1/2" MPT

- FAI 125CA-12E 3/4" Hose ID x 3/4" MPT

- FAI 125CA-16H 1" Hose ID x 1" MPT

- FAI 125CA-20J 1-1/4" Hose ID x 1-1/4" MPT

- FAI 125CA-24K 1-1/2" Hose ID x 1-1/2" MPT

- FAI 125CA-32M 2" Hose ID x 2" MPT

Use With

- Brass

- Steel

- Iron Pipe & More…

Applications

- Air

- Water

- Low Pressure Applications

IDS

TDS

Fairview's Product Catalogue